Internal product code: 502

Product Parameter

|

thickness |

16mm/20mm |

|

Top Coat |

UV protection coating |

|

Surface material |

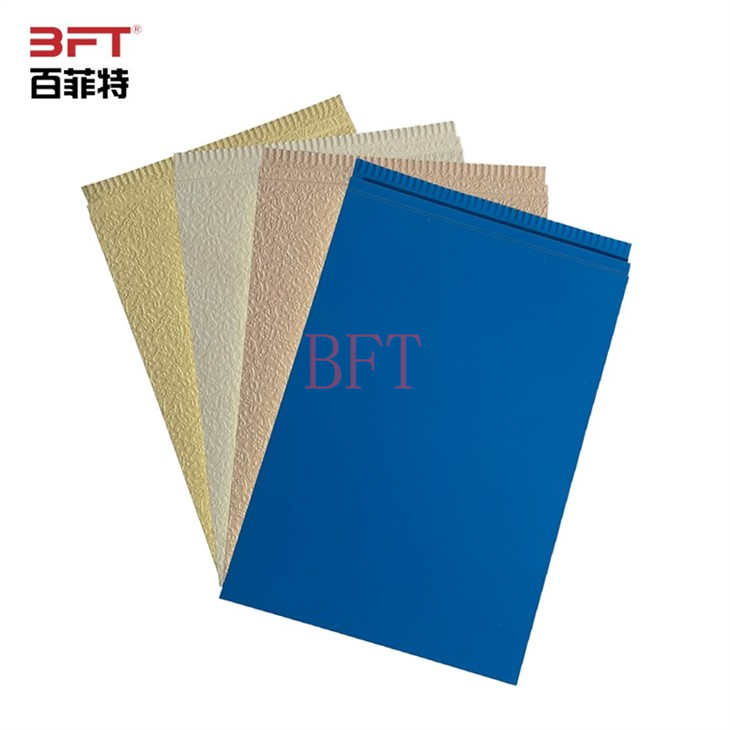

The High-Quality Metal Plate After the Special Coating And embossed Finish Treatment |

|

Core Material |

Rigid High-density PU Foam Thermal Insulation Layer With fire- retardant Treatment |

|

Bottom Side Material |

Foil Protective Layer With The Function of Insulation and Moisture drool |

|

Producing Standard |

ISO9001 ,CE |

|

Width |

380mm |

|

Length |

3800mm(customized) |

|

Package quantity |

8pieces/package |

|

Package Size |

4000mm*430mmx135mm |

|

Thermal conductivity |

0.022W(10℃)/0.0024W(25℃) |

|

Fire Rating |

B1/B2 |

|

payment terms |

FOB Qingdao |

|

Color |

customized |

|

Paint Thickness |

≥30um |

|

Application |

exterior/interior wall decoration, renovation of houses, office buildings, residential buildings, light steel villas, hotels, newsstands, mobile booths, public toilets; etc |

|

Advantages |

lasting beauty; lightweight; fast and easy installation; waterproof; thermal insulation; sound insulation; Eco-friendly;etc |

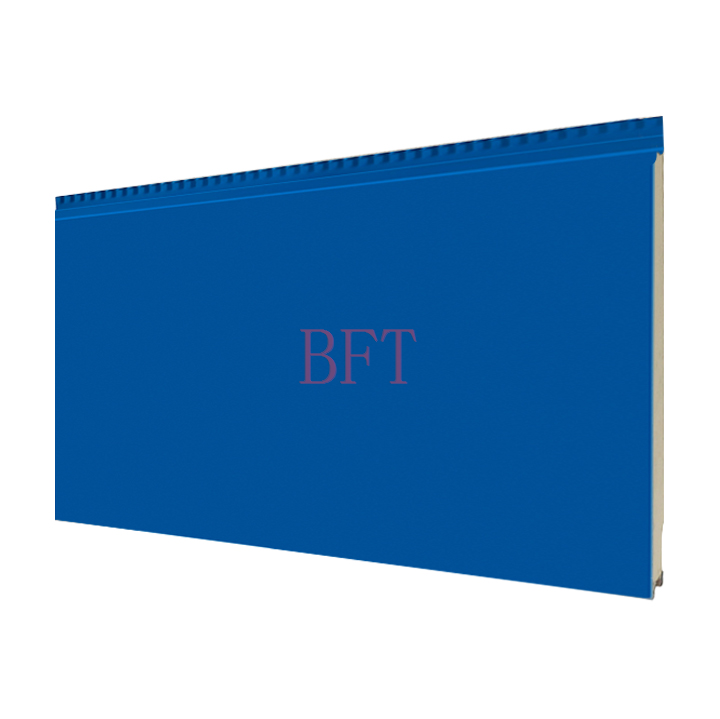

Product Size

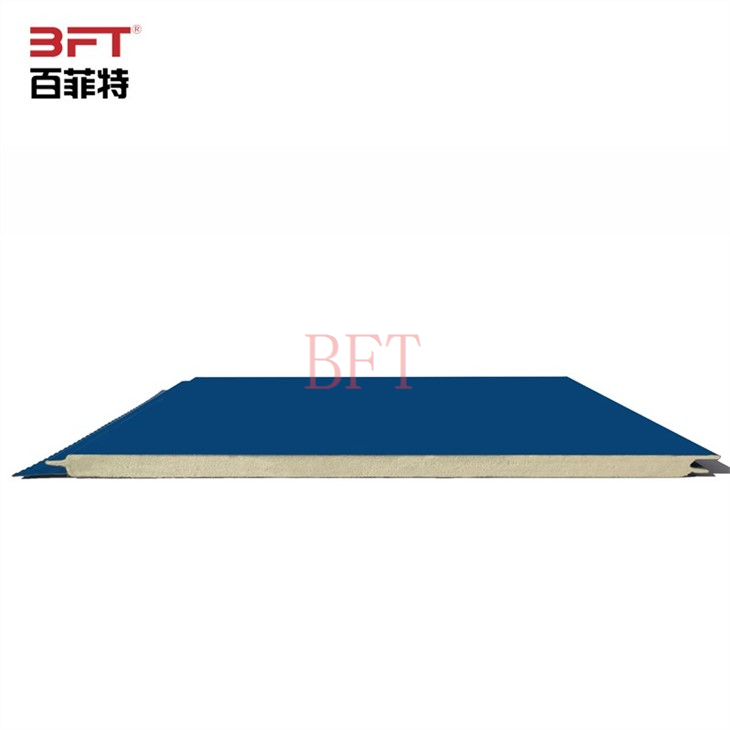

Product Structure

Thermal insulation sandwich panels are commonly used structural materials in construction and industrial equipment, featuring lightweight, high strength, and thermal insulation properties.

The product structure of thermal insulation sandwich panels generally consists of three parts: the facing panel, the insulation core, and the backing panel. The facing panel can be made from various materials such as metal (e.g. steel, aluminum alloy), fiberglass reinforced plastic, gypsum board, etc. The insulation core is usually made of materials such as polyurethane foam, rock wool, polystyrene board, etc., which have good thermal insulation properties. The facing panel and the insulation core are fixed together through a certain adhesive or mechanical connection to form a complete structure.

The structure of thermal insulation sandwich panels may vary according to different usage scenarios and requirements. For example, in some high-temperature environments, materials with high-temperature resistance are required to make the facing panel and the insulation core; in some places with high fire protection requirements, materials with better fire resistance are needed to make the facing panel and the insulation core. Overall, the product structure of thermal insulation sandwich panels mainly consists of the facing panel, insulation core, and backing panel, with specific materials and connection methods determined by the usage scenario and requirements.

Product Features

Lower cost of engineering: The cost of the thermal insulation sandwich panel project is around 1/3 that of the aluminum-plastic panel curtain wall project, and the decorative effect is excellent.

Fast construction: it saves at least 1/2 of construction time than equivalent materials.

No need for grassroots treatment before the renovation of the exterior wall. Just install the panel on the wall directly.

Long service life: Durable years are above 50 years and 15 years without fading.

Heat insulation sound insulation, and noise reduction effect is equivalent to a 5 CM thickness polystyrene board.

Renovation of old houses

For projects in the renovation of old houses, the most important points are the durability and aesthetics of the material. Thermal insulation sandwich panel is a common wall cladding for commercial street and old houses facade renovation. It has good heat preservation, is waterproof, and is very hard to corrosion.

In addition, it has good decoration for different kinds of wall projects.

Product Installation

The installation of thermal insulation sandwich panels generally involves the following steps:

Preparation of construction plan: Before installation, a construction plan should be prepared according to the project requirements, including the size, quantity, installation position, and sequence of the thermal insulation sandwich panels.

Preparation work: Before installation, the installation site should be cleaned and leveled to ensure a flat and firm foundation. In addition, the necessary installation tools and equipment should be prepared.

Installation of facing panel: The facing panel should be installed first, and fixed on the foundation to ensure its flatness and verticality. Screws, rivets, and other methods can be used to fix the facing panel.

Installation of insulation core: Place the insulation core on the facing panel, ensuring its size and position match the facing panel. Then fix the insulation core to the facing panel using adhesive or screws.

Installation of backing panel: After installing the insulation core, install the backing panel, also ensuring its flatness and verticality.

Sealing: After installing the thermal insulation sandwich panels, the joints and edges should be sealed to prevent air and moisture from penetrating and affecting the thermal insulation effect.

Overall, the installation of thermal insulation sandwich panels should follow certain specifications and standards to ensure installation quality and effectiveness. During installation, safety and environmental requirements should be considered to ensure safety and reliability.

Product Accessories

Product Case

Thermal insulation sandwich panels are widely used in various applications due to their excellent thermal insulation, sound insulation, and fire resistance properties, as well as their lightweight and high strength. Here are some common applications:

Building construction: Thermal insulation sandwich panels can be used as exterior wall panels, roof panels, and interior wall panels in various buildings, such as residential houses, commercial buildings, and industrial facilities.

Cold storage and refrigeration: Thermal insulation sandwich panels are ideal for constructing cold storage and refrigeration facilities, such as cold rooms, freezers, and refrigerated trucks.

Cleanrooms: Thermal insulation sandwich panels can be used to construct cleanrooms in industries such as pharmaceuticals, electronics, and biotechnology, where strict environmental control is required.

Industrial equipment: Thermal insulation sandwich panels can be used to insulate industrial equipment, such as tanks, pipelines, and ducts, in order to maintain a stable temperature and reduce heat loss.

Transportation: Thermal insulation sandwich panels can be used in transportation applications, such as trailers, caravans, and trains, to provide insulation and soundproofing while keeping the vehicle's weight down.

Overall, thermal insulation sandwich panels are versatile materials that can be used in a wide range of applications where thermal insulation and other properties are important.

Product And Shipping

FAQ

1/Q: Are you a trading company or manufacturer?

A: We are a factory. you’re welcome to our factory anytime.

2/Q: How long is your delivery time?

A: Generally it is 15 days.

3/Q: Do you provide samples? is it free or extra?

A: Yes, we offer panel samples. It Depends on which Product you’re required.

4/Q. What is your payment term?

We accept the T/T or L/C. And the Ali trade assurance also is acceptable.

5/Q. How is your After-sales policy?

A: We wants to provide the best products and service to each client. We will provide the online after-sales training. If necessary, your can visit us in our factory.

Why choose us?

- With years of experience, we are a trustworthy Chinese manufacturer of Lightweight Insulation Board products.

- We attach importance to the standardization of management, and preach that employees should handle business with clear processes.

- As a Chinese factory, we produce Lightweight Insulation Board products that are of the highest quality and at favorable prices.

- We have all kinds of production and testing equipment and a complete quality management system.

- Our Chinese factory is dedicated to producing high-quality Lightweight Insulation Board products that meet global standards.

- We have professional technology and good management system, together with rich experience and strict quality control, to ensure our consumers get high quality Thermal Insulation Sandwich Panel.

- We are a Chinese factory that specializes in producing Lightweight Insulation Board products to meet the needs of customers worldwide.

- We pay close attention to the construction of style, emphasize the full cooperation of all departments, and clarify the division of labor and cooperation between the main business and the support business.

- With professional expertise and experience, we manufacture and supply Lightweight Insulation Board products.

- We have achieved full management and monitoring of the production process, and all products, raw materials, equipment and personnel can be traced in batches.

Hot Tags: thermal insulation sandwich panel, China thermal insulation sandwich panel manufacturers, suppliers, factory, interior ceiling insulation panels, rigid foam insulation basement, rigid foam insulation between studs basement, overboarding ceiling with insulated plasterboard, insulated skirting board, rigid insulation board