Before deciding on what materials to use for building construction, it is essential to have an understanding of the relevant building panels. This article provides a detailed introduction to sandwich panels that are commonly used in commercial buildings, residential homes, factories, mines, villas, mobile homes, and other structures.

The content of this article is lengthy, and it is recommended that you bookmark or save it for later reading.

The article covers the following aspects in detail:

What are sandwich panels?

How are sandwich panels classified?

Advantages of sandwich panels.

Applications of sandwich panels.

What are sandwich panels?

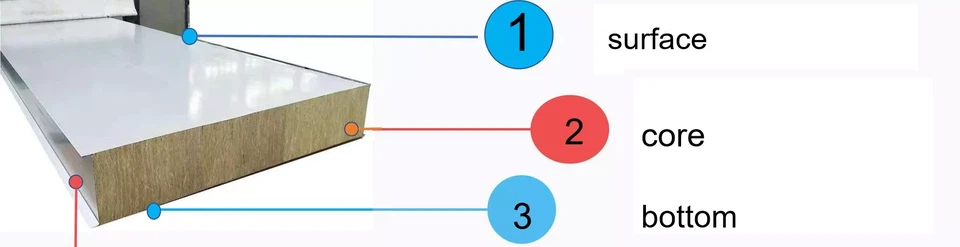

Sandwich panels are generally composed of three layers. The outer layers are made of double-layered metal materials, while the middle layer is a polymer material that is immediately foamed and matured into a shaped thermal insulation core. This structure is lightweight, efficient, and easy to install. The filling system also uses a closed-cell molecular formula to prevent water vapor condensation.

Manufacturers have improved the manufacturing process of sandwich panels according to local usage and consumption levels. Some sandwich panels may have their metal panels replaced with wood or particleboard, and the core layer may be changed to cement board to suit local conditions.

Sandwich panels are a common building material today, and they not only have excellent flame retardant and sound insulation properties but are also environmentally friendly.

How are sandwich panels classified?

The main purpose of sandwich panels is to provide insulation for buildings, and they are mainly classified according to the material of the core layer in the industry. The following are the common types of sandwich panels:

1.EPS-core sandwich panels

2.PUR-core sandwich panels

3.PRI-core sandwich panels

4.Rock wool sandwich panels

5.Cement sandwich panels

6.Gypsum sandwich panels

7.Magnesium glass sandwich panels

8.Aluminum honeycomb sandwich panels

The use of different core layer materials can affect the overall insulation and fire performance of sandwich panels. Insulation performance is a major indicator of building materials, and the important feature of sandwich panels is their R-value. R-value is a common term in the construction industry that refers to the material's ability to resist heat flow or its thermal resistance. The standard wall panel thickness of BFT WALL PANEL is 16mm (although this thickness can be changed to 20mm for specific applications). To increase the R-value of the panel, the insulating part (core material) of the panel should be made as thick as possible, or another material can be used as the core material. Sandwich panels with increased R-value can be used in hotter and colder environments than conventional ones. If the wall panel can keep external heat outside well, it can also keep internal heat inside well.For more detailed information on fire ratings, please refer to《fire ratings》

The fire performance of sandwich panels is mainly reflected in their fire rating. The fire rating is a professional term that can be found by querying relevant information from standard-setting organizations in various countries.

Sandwich panels can also be classified by the material used for the surface layer:

Color steel

Aluminum plate

Wood board

The surface material mainly affects the overall lifespan of the panel. Color steel mainly uses galvanized steel plate as the substrate and uses PVDF/high-weather-resistant paint material and multi-layer painting process to ensure its longer service life, while also playing a role in radiation protection. Color steel has hundreds of colors and can provide customers with more than ten patterns through the rolling process. It can also be customized according to user requirements.

Aluminum outer layer is lightweight, corrosion-resistant, but there may be less flexibility in color and pattern choices.

For wood board outer layer, it is necessary to consider carbonization treatment to ensure fire resistance requirements are met.

The advantages of sandwich panels

Heat preservation

Sandwich panels have good thermal insulation properties due to the insulation material sandwiched between two metal panels. The insulation material used in sandwich panels is usually polyurethane, polystyrene, etc., which have excellent thermal insulation properties. Sandwich panels can effectively reduce the temperature difference between the inside and outside of buildings, improve indoor comfort, reduce energy consumption, and save energy.

Sound insulation

Sandwich panels also have good sound insulation properties. The insulation material not only provides thermal insulation but also sound insulation. The metal panels of sandwich panels can also reflect sound waves, thereby achieving sound insulation effects. Therefore, using sandwich panels for sound insulation in noisy environments inside or outside of buildings can effectively improve indoor quietness.

Quick installation

Sandwich panels are very quick and easy to install. Sandwich panels are made and installed on-site, and the panels can be cut, processed, and assembled on-site according to specific project requirements. Sandwich panel installation does not require a large number of construction personnel and machinery, nor does it require waiting for materials such as concrete to solidify. Therefore, the installation of sandwich panels can greatly shorten the construction period and improve construction efficiency. The use of a tongue-and-groove structure, combined with a wide range of accessories, makes the installation process both more convenient and simpler.

Colour 100+

Sandwich panels have a wide range of colors and can be freely selected according to customer needs. The surface coating of sandwich panels uses modern paint technology, achieving a variety of colors and effects, such as stone, wood grain, texture, etc. Therefore, sandwich panels can meet the different needs of different customers and also beautify the appearance of buildings.

Moisture-proof

Sandwich panels have good moisture-proof properties. The insulation material and metal panels of sandwich panels have both moisture-proof and waterproof properties, which can effectively prevent water penetration. Therefore, using sandwich panels in humid environments can effectively prevent moisture and mold from breeding, maintaining a dry environment inside buildings.

Insect prevention

The metal panels of sandwich panels have good insect prevention properties. The smooth surface of the metal panels of sandwich panels is not easy to breed bacteria, insects, and other organisms, which can effectively prevent pests and pathogens from breeding.

Environmental protection

The materials used in the production of sandwich panels and the use process are both environmentally friendly. The insulation material of sandwich panels is usually made of polyurethane, polystyrene, etc., which can be recycled and reused, reducing resource consumption and environmental pollution. The production process of sandwich panels is also environmentally friendly and does not produce a large amount of pollutants and waste, meeting modern environmental requirements.

Applications of sandwich panels.

The application scenarios of sandwich panels vary according to different core materials and panel types and can be used for industrial factories, public buildings, modular houses, purification projects, and other construction fields. The details are as follows:

(1) Factory/Warehouse: Sandwich panels are mainly used for the roofs and external walls of factories and warehouses. In the past, precast concrete or asbestos panels were mainly used for factory roofs. With the rapid popularity of light steel structures, sandwich panels have replaced the above two materials and have many important advantages. Sandwich panels and mature light steel structures can truly reflect the advantages of lightweight steel systems, such as lightweight, fast, and flexible layout while providing better insulation. Therefore, it is a good solution for single-story factory buildings. In multi-story factories, sandwich panels can not only be used on the roof but also flexibly arranged on the external walls. The purpose is to use colored panels to change the color and shape of the building, making the appearance of the building more beautiful.

(2) Public Buildings: Sandwich panels are mainly used for the roofs and external walls of public buildings that require larger spaces, such as institutions, station waiting rooms, sports halls, theaters, auditoriums, exhibition halls, exhibition centers, and museums. For example, public buildings have a series of higher requirements than industrial factories, because they require more space, indoor air conditioning, and fire facilities. Currently, these buildings mainly use roof trusses of grid or tube truss structures, which have higher requirements. Progress has been made in weight reduction, insulation/sound insulation, fire/waterproofing, and durability.

(3) Modular Houses: Modular houses built using sandwich panels are widely used, with a series of advantages such as lightness, flexible combination, convenient and quick construction, no need for secondary decoration, and convenient assembly and disassembly. Building high-rise houses with sandwich panels is more popular. Due to the lack of land in cities, many units and individuals hope to build an additional floor on the roof without submerging the original building. It not only increases the usable area but also solves the thermal insulation and waterproofing problems of the original roof. The advantages of sandwich panel apartments can fully meet the needs of users. Sandwich panel apartments can be moved multiple times according to your needs, so they are also widely used in temporary housing. In addition, many sandwich panels are used in industrial factories with multifunctional modular shells.

(4) Purification Projects: With the development of society, electronic, medical, and other industries are developing rapidly, and clean production environments must be provided in the production process of products in these industries.

If you found this article helpful, please share it with your friends and colleagues. You can also share our link on social media to help spread the word about our services!

Want to learn more about our services and how to place an order? Click the button below to register now and we'll provide you with more detailed information!